Induction Forging

Induction Forging

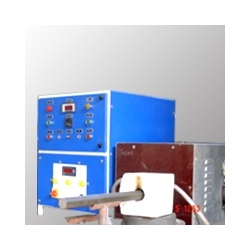

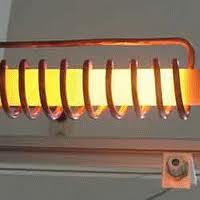

Induction forging technology is a method of plastically deforming a metal accomplished by hammering on a single piece of metal. Materials processed include aluminium, brass, copper, steel and stainless steel. Monad built feeders having a variety of handling solutions including pinch wheel, pusher, walking beam and caterpillar type drive units. The above systems are all embedded controlled and have the ability to monitor or control any parameter requested. Induction bar end heaters utilize a variety inductor designs depending upon the associated handling system in the unit. Typical concepts include conveyors, pick and place, v block, rotary table and pneumatic cylinder pusher systems. All the above systems can be tailored to customers exact requirements. The industry norm is to have a standard unit which does not allow flexibility or the customer to integrate features that would benefit their specific process. Monad believe in consultation as no two applications or customers are identical. We manufacture systems bespoke allowing input from the customer and providing the optimum solution for your particular process.

Both mf and rf power units are available

Handling systems suitable for both billet heating and bar end heating

Repeatable, controllable heat

Reduced energy costs

Less oxidation of component improving tool life

Send Enquiry