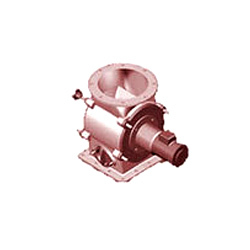

Flash Dryer

Flash Dryer

With just single operation, the dryer provides homogeneous mixing, heat transfer, and mass transfer to dry a solid. The residence time in the dryer is usually less than three seconds, producing almost immediate surface drying. It is due to the rapid drying process, these are suitable for diffusion-controlled drying processes.

Feeds used are:

- Moist, powdery, granular, or crystallized

- Wet solids discharged from centrifuges, rotary filters, and filter presses

- mall in particle size

- Reasonably dry, friable, and not sticky

Advantages :

- Relatively simple in operation

- Take little space

- Generally require lower capital investment than other types of dryers

- Excellent choice for processing heat-sensitive or easily oxidized feed materials

- Product inventory in the flash-drying system is very low

- Easy to change product or product grade with minimum downtime

- Control of the flash-drying process is very simple

- Control system responds very quickly to operational changes

Design Considerations :

- The flash drying systems are designed based on feed and product characteristics, which include permissible heating source, and operational safety requirements

- Can be designed in a closed-cycle arrangement, making it suitable for evaporation of organic solvents rather than water

- The drying gas is inert (typically nitrogen), and the solvent evaporated in the flash dryer is subsequently condensed