Broaching Machine

Broaching Machine

Machine table The table is single station depending on customer requirement A ring is fitted at the bottom of the machine table so as to facilitate opening of broach holder when it comes in contact with the ring. It has T-slot to mount fixture.

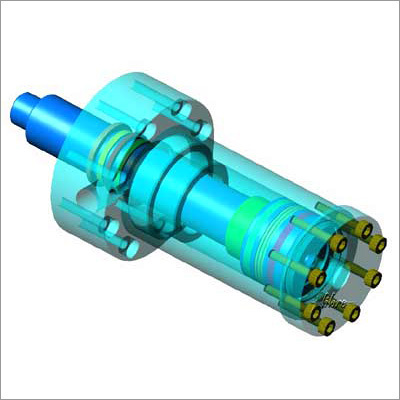

Drive The drive to the moving plate is through the one hydraulic cylinders for machines. The cylinder is connected to a very well designed hydraulic powerpack. The power pack delivers force required for broaching operation.

Speed For Broaching machine is possible to change the speed of the machine by flow control valve provided on the power pack while load can be adjusted by valves. After cooler is also provided on the machine on special request if the ambient temperature of the work place is high specially in summer.

Coolant unit An efficient coolant supplies sufficient coolant oil from top. There is also the provision of oil flow on the broach through the machine table by a series of holes drilled in the machine bed. This helps to clean the chips from the broaching tool.

Stroke adjustments The positioning of the stroke is adjusted by two limit switches. Two additional limit switches at the upper and lower reversal point of the machine can be provided for security reasons.

Safety The machine in operation requires the two push buttons mounted on the front of the machine. To be pushed by both hands. This avoids the risk of hand of the operator to be in the machine while in motion. Thus risk accident is totally avoided.

Note We can also manufacture broaching machines as per requirements, for example 10Ton x 800 stroke.

Broaching Fixtures These are used where workpieces require fixing or where a definite position of the broach is necessary.