Ripening Chambers

Ripening Chambers

Ripening is the process by which fruits attain their desirable flavour, quality, colour and other textural properties. On the basis of ripening behaviour, fruits are classified as:

Non-Climacteric Process: Fruit does not ripen after harvest. Non-climacteric fruits once harvested never ripen further. Non-climacteric fruits produce litter and no ethylene is produced and there is no large increase in CO2 production. Non-climacteric fruits are citrus, pineapple, grape, strawberry and cherry.

Storage capacity of ripening chamber may depend on fruits to be ripened and stacking and air-flow system. In this context, banana may be taken as reference crop for calculation of storage capacity for a given volume of storage space.

a. Ripening Room dimensions will depend on number of tiers and number of pallets to be stored. On an average 9M3 per MT of banana fruits in CFB boxes and 10 M3/MT in plastic crates may be assumed for calculation of capacity in MT in pressurised chamber.

b. Number of chambers may vary from four to eight depending on ripening cycle in terms of number of days. Chambers will be generally identical in dimension.

c. Further Increase in number of chambers in multiple of ripening cycle may be undertaken but situation in which mechanised handling is possible it would be better if multi tier ripening chamber is undertaken. The number of tiers may go up to three.

d. Pressurised Ripening Room Door is designed for minimal gas leakage. As manual handling is common in India (including manually operated forklifts), sliding doors with rubber seal are commonly used.

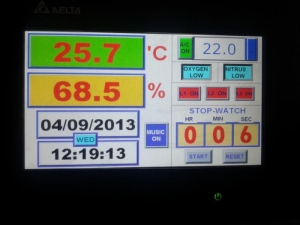

e. Ripening is preferred at a lower temperature but above level of chilling injury. Desirable ripening conditions for the designated fruit may be (Temp 10o C to 23o C) at RH >90% up to 95%.

f. Cooling and heating system needs to be designed based on heat load calculation. Freon R407/410 is generally used as refrigerant for small installations and Ammonia for larger industrial applications. Any other eco-friendly refrigerant may be used.

g. Ethylene gas with suitable detection and dosing equipment to maintain ethylene concentration within required levels depending on product (Range 10 to 200 ppm).

h. Minimum air flow should be 2000 M3 per hour, per MT of product ripened at 95%.

Send Enquiry

.jpeg)

.jpeg)