Ultrasonic And Flux Leakage Equipment

Ultrasonic And Flux Leakage Equipment

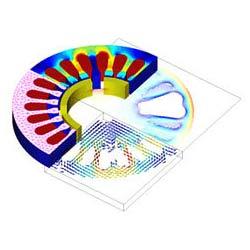

We manufacture a precision engineered range of Ultrasonic & Flux Leakage Equipment that provides 32 ultrasonic testing channels and is appreciated for its outstanding performance for in-line flaw detection and thickness and inside diameter measurement, in a Windows® XP platform. These are provided with user configured flaw detection or thickness gauging for each channel and features: •Four independent flaw gates in each ultrasonic channel •Simultaneous a-scan and strip chart display of up to 16 channels •Adjustable pulse firing sequence to avoid crosstalk in multi-channel applications There is present a flicker free A-scan display which captures non-repetitive events such as flaws of short duration, even in very high speed ultrasonic testing systems, typical of rotating transducer heads. There is also present a strip chart display which shows the peak values of signals within each threshold gate, for up to 16 channels. There is also present a display mode that includes basic sample mode, persistence mode with adjustable decay time, and a dynamic 3-D mode where in the prior signals fade into the background as the displacement of the transducer and reflector changes. Full network support is available for viewing and controlling the instrument from a remote desktop. The software also includes: • Test signal recorder • End suppression • Tracking system • Production logging • Multi-channel view • Channel mapper with alarm routing screen to assign multiple thresholds to the desired output devices Typical Application: • Well suited for new or older installations in need of upgrading, the FD-4 instrumentation is used with MAC\'s Echomac Rotary Ultrasonic Transducer assembly as well as with other existing immersion or squirter type "spin the tube" installations • Flaw, thickness or ID diameter detection on or off line, for tube, bar, or plate

Send Enquiry