FRANCIS TURBINE TEST SETUP (1 13 HP 2 HP 5 HP) HM 101

FRANCIS TURBINE TEST SETUP (1 13 HP 2 HP 5 HP) HM 101

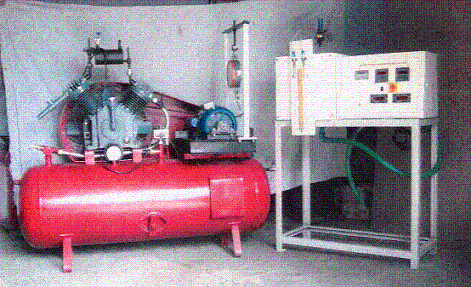

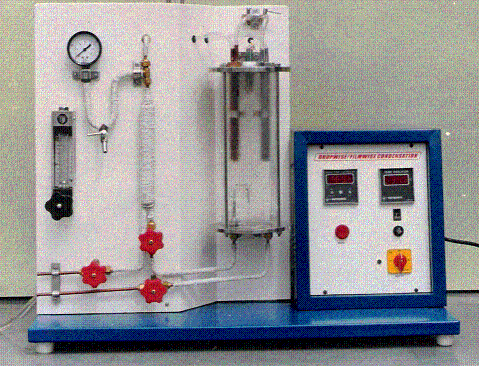

The present Set-up consists of a runner. The water is fed to the turbine by Means of centrifugal Pump, radially to the runner. The runner is directly mounted on one end of a central SS shaft and other end is connected to a brake arrangement. The circular window of the turbine casing is provided with a transparent. The circular window of the turbine casing is provided with a transparent acrylic sheet for observation of flow on to the runner. The runner assembly is supported by thick cast iron pedestal. Load is applied to the turbine with the help of brake arrangement so that the efficiency of the turbine can be calculated. A draught tube is fitted on the outlet of the turbine. The Set-up is complete with guide mechanism. Pressure and vacuum

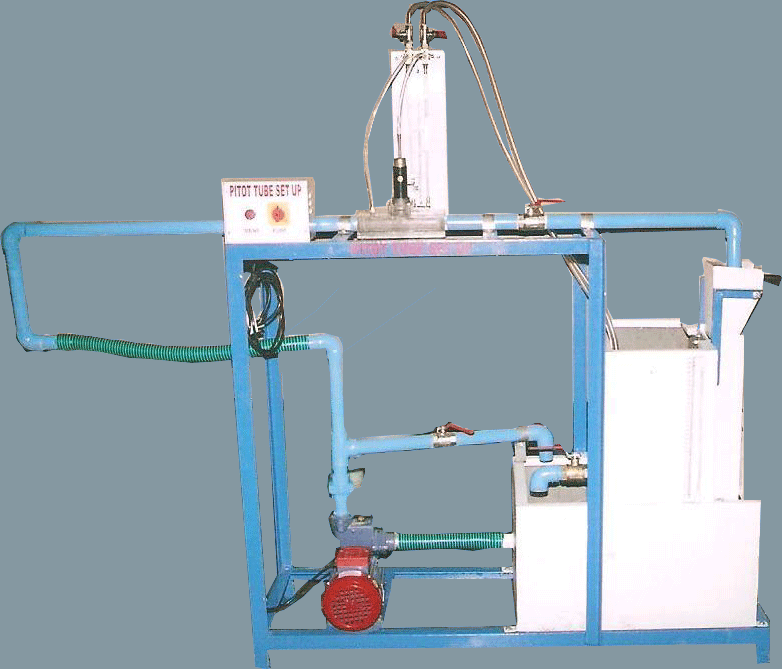

Gauge are fitted at the Inlet and Outlet of the turbine to measure the total supply head on the turbine. EXPERIMENT:- To study the operation of a Francis Turbine To determine the Output Power of Francis Turbine To determine the Turbine Efficiency UTILITIES REQUIRED:- Water Supply and Drain Electricity 15 kW, 440V Ac, Three Phase Floor Area 1.5 x 0.75 m SPECIFICATIONS: - MODEL HM 101 (1.33 HP) HM 101 (2 HP) HM 101 (5 HP) Output Power 1.33 HP / 1 Kw 2 HP / 1.5 Kw 5 HP / 3.75 Kw Discharge 1000 LPM (Approx.) 1000 LPM (Approx.) 2000 LPM (Approx.) Supply Head 10 m 10 m 15 m Rope Brake Dynamometer Dia 200 mm Dia 200 mm Dia 300 mm Sump Tank Capacity 300 Ltrs. Capacity 400 Ltrs. Capacity 600 Ltrs. Water Circulation Centrifugal Pump Capacity 5 HP, Three Phase Capacity 7.5 HP, Three Phase Capacity 15 HP, Three Phase Speed 1500 RPM (approx.) Runner Having Curved Vanes Discharge Measurement Pitot Tube with Manometer Control Panel Star/Delta Starter, Mains Indicator, MCB for overload protection Tanks will be made of Stainless Steel The whole set-up is well designed and arranged in a good quality painted structure.

.jpg)

.jpg)

.jpg)