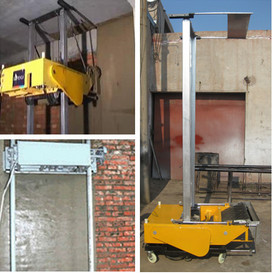

Grouting Mortar Spray plaster Machine

Grouting Mortar Spray plaster Machine

Grouting Mortar Spray plaster machine applications 1.Plugging engineering applications water leakage of expansion joint, subway, tunnels, mine plugging, leak-proof projects, dams & other flood water leakage plugging projects. 2. Structure reinforcement projection applications Crack reinforcement, bridge reinforcement, floor reinforcement. 3. Coating project materials Js waterproof material, cement-based capillary crystalline waterproof(CCCW) coating, polyurethane waterproof coating, waterproof agent, indoor and outdoor spraying, cement mortar, dry mortar, putty powder, emulsion paint, stone paint, 4:Waterproofing Spraying Projects: Suitable for indoor and outdoor spraying ,cement mortar spraying ,dry powder mortar spraying ,putty powder spraying ,waterproofing material an waterproofing surface spraying ,ceiling spraying ,wall spraying .coating/painting spraying ,gardening spraing ,relief effect coating ,art and craft spraying ,emulsion paint,stone-like paint,manmade rock spraying ,carving and sculpture spraying ,damping material spraying and other spraying project . Spray operational rules: 1. Before starting, add fresh water into the hopper and regulate the speed to the middle-high speed in order to achieve the effect of wetting pipe, only a short running and then draining the water. 2. Putting the even material stirred into the hopper, and then locking pulp exit of main machine and the pipe & nozzle. 3. Before spraying, filling the pressure of air compressor to 8kg (matched air compressor 0.26-0.36m) and then connected to the nozzle. 4. After connecting to power, putting the gunpoint aiming the hopper, adjusting the air pressure and the speed until achieving the best state of fogging, shutting down the machine but non-stop wind. 5. After the accurate Debug, immediately move the nozzle and spray jets to the construction site work. 6. During the construction process, the pipe is filled with paints, not suitable for parking too long. If the power is failure, you should immediately dismantle the pipe to clean. 7. If filling pressure in the pipe, before dismantling & cleaning, you must put the cloth on it to protect your eyes, avoiding injury. 8. If starting the machine fails, first check whether the fire drills is broken or not and should replace it immediately. 9. Cleaning the body during the working or completion, making sure wetting the electric drill & box, avoiding damage. 10. After completion of working, must clean up the hoppers, pipes, nozzles, and rotary joints so as to work tomorrow 11.If detecting the exit of paint is weak power after a long time to work, you have to replace the pressure pump. 12. If it suddenly appears without feeding material in the work, while motor is still working, it proves that the nozzle has been plugged. You should immediately stop working and clean the nozzle, and then continue to work. 13. Nozzle is damageable (including the pressure pump). The standard nozzle pore is 4mm. When the fogging of

Send Enquiry