PCD Tool

Home / Products/Services / / PCD Tool

PCD Tool

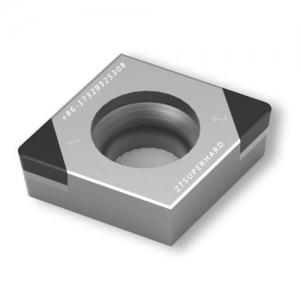

PCD Cutting Tool Blanks: PCD cutting tool blanks are produced by sintering selected diamond particles at high pressure and high temperature, and consist of diamond layer and tungsten carbide substrate. PCD Blanks provide the hardness, abrasion resistance and thermal conductivity of natural diamond, combined with the toughness of tungsten carbide. The work piece processed by PCD has good surface finish and no need being ground. It is an ideal tool material for its long life and high efficiency. PCD is widely used for the machining of non-ferrous metals and alloys, such as aluminum, copper, aluminum / gray iron composites, as well as nonmetallic materials such as wood, chipboard, ceramics, plastic, rubber etc, where high abrasion resistance and good surface finish are required. The products are available in 5μm, 10 μm, 25 μm, 2505 μm and 3002μm. Advantages Of PCD Tool Blanks: Long life tool Uniform surface finish Reduces machine down time Highly improved work piece quality and excellent dimensional control Increase productivity High material removal rate Lower cost per piece Standard diamond layer thickness is 0.8-1.0mm. Available in three grades: 5μm、10μm、25μm、2505μm、3002μm Typical order code: R360/10.0-3.2-05 Product Number R360/10.0, Overall thickness:3.2mm, Grain size:5μm Further details about vitrified bond grinding wheels,please check http://www.ztsuperhard.com/Tool/PcdCuttingToolBlanks.html

Send EnquiryRelated Products

Products / Services

- Pcd Inserts

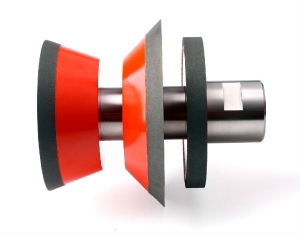

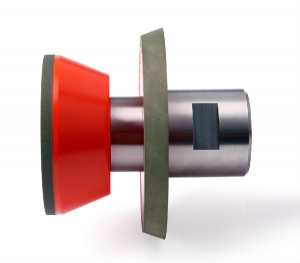

- Vitrified Bond Grinding Wheel

- Resin Bond Cutting Wheels

- Centerless Grinding Wheel

- Diamond Bruting Wheel

- Cnc Grinding Wheel

- Metal Bond Cutting Wheels

- Pcd Cutting Tools

- Pcbn Cutting Tool Blanks

- Pcbn Cutting Tools

- Pcd Cutting Tool Blanks

- Pcd Tool

- Pcbn Tool

- Cbn Inserts

- Pcbn Inserts

- Diamond Inserts

- Diamond Grinding Wheels

- Metal Bond Dicing Blades

- Metal Bond Saw Blade

- Resin Bond Dicing Blades

- Resin Bond Saw Blade

- Resin Bond Grinding Wheel

- Diamond Grinding Wheel

- Vitrified Bond Diamond Wheel

- Cnc Tool

- Cnc Diamond Wheels

- Cnc Grinding Wheel

- Cbn Grinding Wheels

- Diamond Grinding Wheels

- Diamond Bruting Wheels

- View All