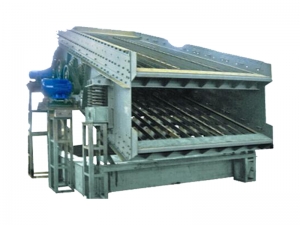

Lump ore screen

Lump ore screen

Overview: 1. Exciter and damping spring of lump ore screen are located within the screen box. 2.Vibrating part is completely contained inside the sieve, and the outside sieve body does not vibrate. 3. Using two motor drive. 4.Lump ore screen has a single-layer double-sided self-cleaning cantilever rods, maintenance-free exciter, combination of sealing structure and other components. 5.Exciter directly driven sieve plate vibration, and the sieve body does not participate in vibration. Amplitude :15mm-25mm. Features: 1.Vibration motor install in the sieve outside, is conducive to the maintenance of motor replacement. 2.Using single-layer double-sided self-cleaning cantilever rod, effectively solve the plugging phenomenon, improve the screening efficiency. 3.Exciter is through the two ends of the two drive shaft connected together structure, this structure reduces the weight of the bearing chamber. 4. Exciter inside the package in the sieve box to reduce noise and increase personal safety. 5. Exciter with thin oil lubrication, a oiling, maintenance-free process, an effective solution to the grease lubrication high temperature of the drawbacks of poor lubrication. 6.Self-heat dissipation: The use of hollow shaft structure, the hollow shaft with rotating vents connected ventilation holes, so that the shaft during rotation in the shaft temperature through the blade rotation out of the shaft. 7.Combination seal structure: the overall structure of the exciter with a complete sealing arrangement, bearing room and support plate, between the maze cover and the rotating shaft, through-hole cover and bearing room contact surface, through-hole cover and sleeve and so on Increase the seal, effectively avoid oil leakage when the exciter rotates. 8.Excitation source and screen box sealed between the use of special rubber made of special seals, with high wear resistance, flexibility and other advantages.

Send Enquiry

.jpg)

.jpg)

.jpg)

.jpg)