Concrete Cooling

Concrete Cooling

Concrete Cooling

At Icelings we offer a wide range of concrete cooling solutions for the construction industry. In construction of dams, tunnels, bridges, and sewage plants etc; it is of utmost importance that temperature of the green concrete is controlled so that these buildings can withstand tensions that are created in finished concrete structure. Excessive internal heat-up of the green concrete especially in hot climates has to be avoided in order to prevent cracks and maintain proper strength, ensure consistent quality, and eliminate cracks.

HEAT OF HYDRATION

On mixing cement used in concrete with water heat is liberated which is known as the heat of hydration formed by the exothermic chemical reaction between cement and water. This heat of hydration raises the temperature during the curing process by up to 25° causing an increase of volume. After the curing the concrete cools down again reducing its volume and thus naturally causing cracks eventually. Therefore the initial pouring temperature should be lowered so much that the maximum temperature during the curing process does not exceed a certain temperature determined by the consultants.

OUR PRODUCTS SERVING THE CONCRETE INDUSTRY INCLUDE

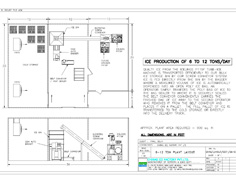

The following components are consisted:

Water Chilling Plant for the total amount of mixing water

Cold Water Tank with Pumping Station

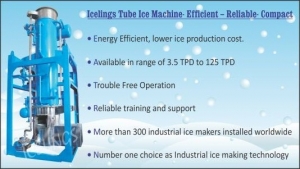

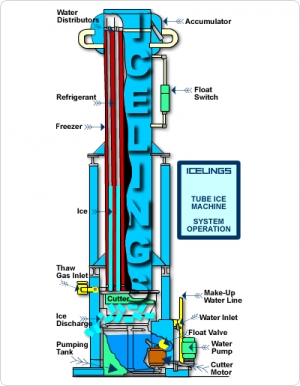

Tube Ice Plant (10 to 140 tons per day)

Tube Ice Storage with fully-automatic Ice Rake and Discharge System

Tube Ice Delivery

Tube Ice Weighing

Aggregate Cooling System

Post-Cooling of the concrete

All components are available with different options.

Send Enquiry