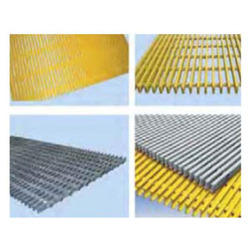

Pultruded Grating

Pultruded Grating

Pultruded Grating

We are delicately engaged in offering a qualitative range of ACL Pultruded Grating. This product is precisely manufactured using premium quality raw material and contemporary techniques by our professionals. Moreover, this product is widely demanded in domestic markets. Our product is used in agricultural, chemical, aerospace, construction, sports, automotive, transportation, ship building and tourism industries. The offered product can be obtained at industry leading rates within the promised time-frame.

Features:

Higher Stiffness:

ACL Pultruded Grating is manufactured with every panel of grating subjected to a sequence of quality assurance inspections ensuring complete sealing of all joints, full wet-out of the glass ravings, consistent resin-to-glass ratios, and consistent non- skid features. ACL Pultruded grating is lightweight, strong, chemical and UV resistant, and reduces costly maintenance. ACL pultruded grating is particularly well suited for highly corrosive environments and offers extended life, eliminating periodic maintenance and replacement costs, thus making ACL pultruded gratings the preferred alternative to conventional steel gratings.

Higher Stiffness:

ACL pultruded grating possesses approximately 65% glass and 35% resin content by weight, giving it a very high strength to weight ratio. Load bearing bar capacity can be tailored to the application by modifying the glass content, berorientation, and combination of mat and roving reinforcement.

Chemical Resistance:

ACL pultruded gratings offer superb chemical resistance to variety of acids and caustics. ACL pultruded grating is offered in an array of corrosion resistant resins designed for any environment, from light or moderately corrosive environments to extremely corrosive applications.

Lightweight:

ACL pultruded grating weight much less than comparable steel gratings-as much as 50%-75% weight savings can be realized depending on the bearing bar configuration. For weight sensitive structures, such as a tension-leg platform for an offshore deepwater facility, the use of ACL pultruded grating offers significant weight savings, thereby reducing the overall cost of the project.

UV Resistance:

All ACL pultruded gratings are manufactured with resins containing UV inhibitors. UV resistance is enhanced with the use of a synthetic surfacing veil, creating a “resin rich” surface, and further strengthening ACL pultruded grating resistance to UV attack.

Impact Resistance:

ACL Pultruded Gratings offer better impact resistance than conventional steel gratings.

Fire Retardancy:

All ACL pultruded gratings are designed to exhibit same spread rating of 25 or less test in accordance with ASTM E-84 tunnel test, and meet the self-extinguishing requirements of ASTM D-635. A variety of resins are available offering an array of same spread ratings and smoke densities.

Send Enquiry