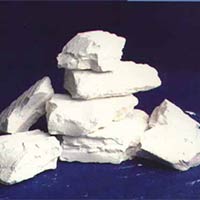

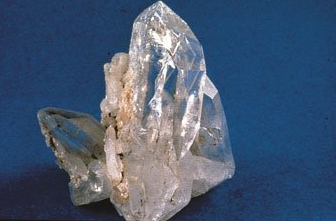

Calite

Calite

We are proud to reckon as one of the topmost Calcite Powder Exporters from India. We offer finest quality Calcium Carbonate Powder that is known for its purity, whiteness and free flowing nature. Used in various applications such as in rigid PVC pipes, pain, ink, powder coating and ceramic industry. Good dispersion properties of Natural Calcium Carbonate Powder make it widely recommended by our esteemed customers. In addition to this, Calcium Carbonate Powder is also available in different quantities and packing as per the requirements of patrons. Natural Calcium Carbonate Powder can be obtained at the most competent prices.

Typical Properties of Calcite :

- Higher flow properties

- Higher mechanical properties in thermoplastic applications

- Better gloss and whiteness in Paints & Powder coating applications

- Excellent dispersion properties

- Prevents chalking

- Better corrosion resistance

Application of Calcite :

- Paints, Inks, Powder Coating & Ceramic Industry

- PP master batches, Automotive & Furniture compounds

- LDPE masterbatches

- Rigid PVC Pipes

- Leather Cloth Industry

- Rubber Industry

- As a flux in Glass Industry & in sizing of Textile goods

Our grades of Calcite powder are available in 300 Mesh to 700 Mesh BSS standard & in Micronise grades, Our grades are available in top cut 5, 10, 15 & 20 Microns.

Chemical Composition Of Calcite :

- CaCO3 93% to 99.5%

- MgO 1.5% to 2.5%

- Silica 1 % to 3.5%

Variation of the specifications stated due to natural raw materials & environment conditions are possible. though they have no influence on the application properties described.

Surface Treated Calcite

We also do coating on Calcite powder. We provide coating of Steric Acid. The Coated Calcium Carbonate powder is used in plastic compounds manufacturing to avoid moisture contains. Coating is done from 1% to 3% or as per customer requirement.

Typical Properties of Surface Treated Calcite :

- Rapid and complete dispersion

- Low abrasion at higher loading

- Low moisture content

- Good compatibility with Polymers & other additives

- Increased flow rate

- Reduced plasticizers & other additives

- Better HDT

- Better Impact strength

- Better dispersion

- Lower raw material cost

.jpg)